Canada’s Potash Legacy

A Road Trip Through 40% of the World’s Food Fertilizer Production

Canada is the world's largest producer and exporter of potash accounting for nearly 38% of the global potash supply, a mineral critical to global agriculture.

Potash, primarily used as a key ingredient in fertilizers, enhances crop yields, strengthens plant resistance to pests and diseases, and improves drought tolerance. With a growing global population and food demand projected to double by 2050, Canada's leadership in potash production is more vital than ever.

Most of Canada’s potash reserves are in the province of Saskatchewan. This region, hosting some of the richest Potash deposits on the planet, is home to ten active mines and several major development projects. In 2022 alone, these mines produced approximately 24.6 million tonnes of potassium chloride (KCl). The province's extensive rail and export infrastructure further amplify its role in feeding the world.

The potash industry in Canada is a sponsor of many large engineering megaprojects, such as BHP’s Jansen Potash Project, one of the largest capital investments in the sector globally. These projects are engineering marvels and underscore the industry's role as a catalyst for innovation, sustainability, and growth within the heavy industry construction sector of Canada.

In this article we review,

Potash and Potash Mining Methods

History of Canada’s Potash Industry and its Highlights

Saskatchewan Potash Reserves and Operating Mines

Canada’s Potash Transportation System

Capex Requirement of Potash Megaprojects

The Curious Relationship of Potash and Climate Change Adaptation

From Calgary, to Saskatoon, to Winnipeg, we embarked on a 14-hour long road trip to witness the heart of Canada's agricultural legacy, not to mention the vibrant city of Saskatoon. This road trip left us with a much deeper appreciation of Canada’s role in feeding the world.

Voyage and Return

Last year, our research group planned a trip to Winnipeg for a joint conference. The idea of turning it into a road trip through Canada’s potash heartland seemed exciting at first. But once we realized it involves a 14-hour drive, our enthusiasm quickly faded away.

As we dug deeper into Canada’s rich potash legacy, the road trip idea grew on us. Our most viable plan was to rent a car, leave Calgary at dawn, and to fly back from Winnipeg. After weighing the pros and cons, we decided to put it to a group vote. Unanimous, the road trip won.

What followed was an unforgettable journey through some of the world’s largest potash mines and the impressive transportation networks that make this industry possible. A proud legacy for Canada. Looking back, it was definitely a long trip, but the experiences and insights we gained, and sharing them with you, will make it worthwhile.

Potash

Potash, derived from the Dutch "potasch" meaning "pot ash," is used to describe a variety of potassium-bearing minerals and compounds.

This term originates from the traditional method of extracting potassium carbonate by leaching wood ashes in pots. Today, "potash" primarily refers to potassium chloride (KCl), but also includes potassium sulfate (K2SO4) and potassium nitrate (KNO3), all crucial for manufacturing fertilizers.

Potash is a key ingredient in fertilizers that improve crop yields, enhance plant resistance to diseases and pests, and increase drought tolerance. Potassium is vital for plant health, aiding in functions like photosynthesis, water regulation, and disease resistance. These benefits make it indispensable in modern farming practices, especially as the global population and food demand continue to rise.

The limited availability of Potash poses significant challenges to agricultural growth. With the global population rising and food demand expected to double by 2050, potash has becoming an increasingly vital mineral (1). The mining of potash involves extracting these potassium-rich minerals from underground ore deposits, which are then processed into usable forms for agriculture (2).

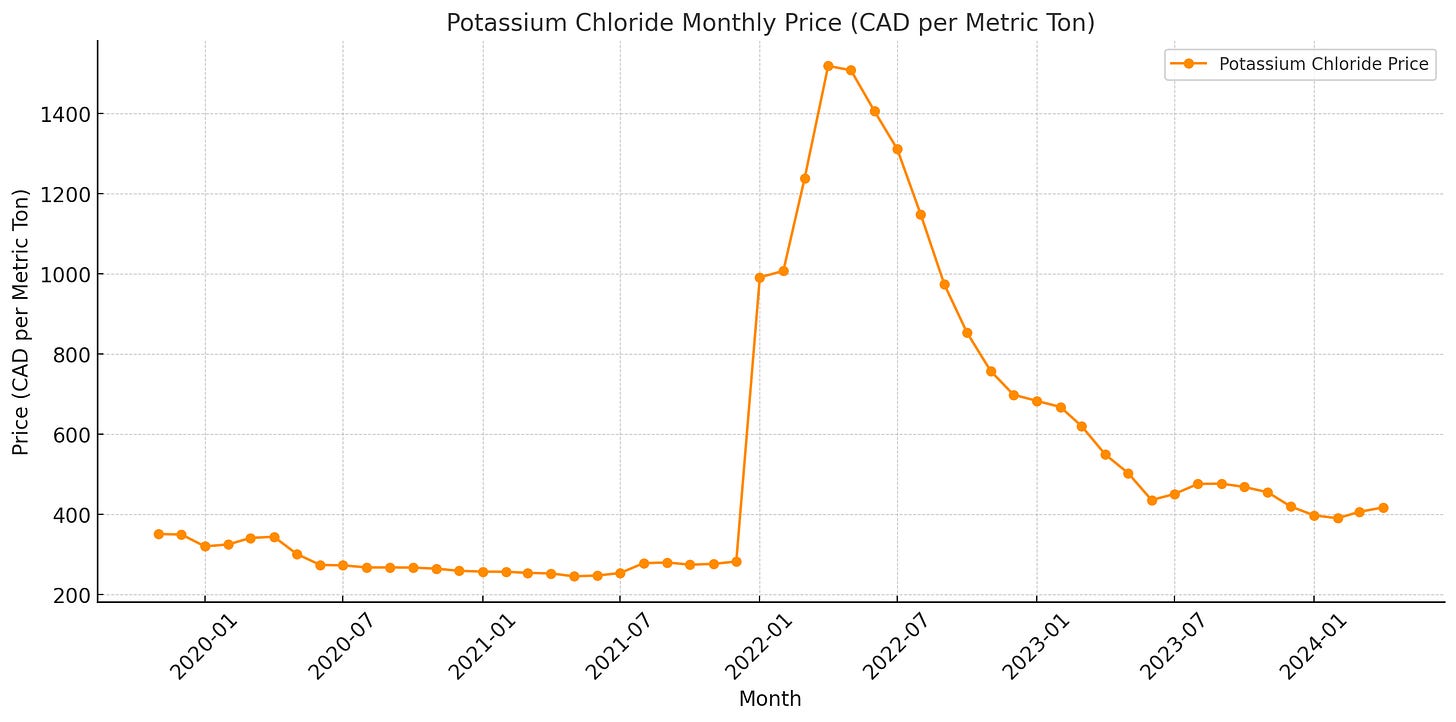

Before the pandemic in 2021, potash prices comfortably sat between CA$250 and 280 per metric ton. But as the pandemic unfolded, the disruptions in supply chains, heightened demand for agricultural inputs, and geopolitical pressures caused prices to soar to more than five times the pre-pandemic levels, reaching over CA$1,500 per metric ton in early 2022.

Today, prices have begun to stabilize, settling around CA$400 to 450 per metric ton, about 1.5 to 2 times pre-pandemic levels.

Potash Mining

There are two primary methods for potash mining: conventional underground mining and solution mining.

Conventional underground mining involves excavating deep shafts to access deposits at depths of 900 to 1,100 meters, where machinery and workers extract the ore. This is most suitable for shallow, high-grade deposits and is widely used across seven mines in Saskatchewan.

In contrast, solution mining, used at three mines, targets deeper deposits up to 1,500 meters, or is used to extract from disturbed or abandoned former underground mines, of instance due to previous flooding. This less invasive technique involves injecting water to dissolve potash into a brine solution, which is then pumped to the surface (4).

We will compare the capital cost requirements of these methods further in this article.

The processing of potash includes refining the material to remove impurities and increase the concentration of potassium chloride through techniques such as flotation, crystallization, and drying.

Canada’s Potash Industry

Economically, potash is a cornerstone of Canada’s resource sector. The industry contributes 23 billion of dollars to Canada annually, supports 76000 jobs (5), and contributes to the economic development of rural and Indigenous communities. Canada’s extensive transportation infrastructure, including railways and ports, facilitates the efficient export of potash, ensuring its accessibility to global markets.

History

1940s: Early Inspiration and Exploration – Potash exploration in Canada began, inspired by discoveries in Germany and the United States, driven by rising global demand for agricultural fertilizers.

1943: Accidental Discovery – Potash was discovered in Saskatchewan during routine oil drilling, but its significance wasn’t immediately recognized due to low market demand and focus on oil.

1950s: Rising Demand and Focused Surveys – Global demand for potash grew, prompting geological surveys in Saskatchewan that revealed extensive deposits suitable for mining.

1958: Birth of Canada’s Potash Industry – The first potash mine near Saskatoon was opened by the Potash Company of America, officially starting Canada’s potash production.

1960s: Expansion Era – Potash demand surged, leading to the opening of several new mines in Saskatchewan and a significant increase in production capacity.

1970s: Oversupply and Industry Challenges – A global surplus of potash caused price drops and reduced production, prompting industry consolidation and technological advancements for efficiency.

1980s–1990s: Stabilization and Innovation – The industry stabilized with moderate growth driven by innovations in mining and processing, improving both output and environmental sustainability.

2000s Onward: Renewed Expansion – Rising global food demands led to increased production and expansion, with companies like PotashCorp (now Nutrien) playing a major role.

Today: Saskatchewan’s Global Leadership – Saskatchewan is the largest potash-producing region worldwide, holding nearly half of the global reserves.

Innovation

The Canadian potash industry has a legacy of innovation that has propelled it to global leadership.

Early mining efforts faced significant geological obstacles, including severe water inflows during shaft sinking. To address this, ground-freezing techniques were pioneered, enabling safe and stable underground mining. These breakthroughs laid the foundation for Canada’s potash sector to flourish (6).

In 1964, Kalium Chemicals Ltd. opened the world's first potash solution mine near Regina. The introduction of solution mining allowed access to reserve unreachable by conventional mining techniques. It not only expanded production capabilities but also demonstrated the industry's adaptability to complex geological conditions (7).

In the 2000s with the Saskatchewan Research Council (SRC) developed new potash assay methods, becoming one of the world's largest potash assay laboratories. This supported the industry's growth by providing accurate analysis for exploration and production (8).

Today, the potash industry continues to lead with innovations focused on sustainability and efficiency. Practices such as water recycling, land reclamation, and digital optimization are now integral to mining operations. This enduring commitment to innovation ensures that Canada remains at the forefront of the global potash market while contributing to more sustainable agricultural practices worldwide (9).

Social and Economic Impacts

The potash industry is a vital pillar of Saskatchewan's economy, significantly contributing to both the province and Canada as a whole.

In 2022, it added approximately CA$8.6 billion to Saskatchewan’s GDP and generated CA$5.4 billion in tax revenues across federal, provincial, and local governments. This financial impact highlights its critical role in sustaining public services and supporting economic growth.

Over the past 15 years, Saskatchewan has attracted CA$30 billion in investments for new mines and expansions, showcasing the industry's dynamic growth. On a national level, Canada’s fertilizer industry, anchored by potash, contributes roughly CA$23 billion annually to the economy and supports over 76,000 jobs across the country. As demand for agricultural fertilizers continues to grow globally, the Canadian potash industry remains a cornerstone of economic stability and innovation (10, 11)

Saskatchewan Potash Reserves and Operating Mines

Saskatchewan is a province in the heartland of Canada known for its vast horizons and rich agricultural land.

It is bordered by Alberta to the west, Manitoba to the east, and the Northwest Territories to the north. Saskatchewan is famous for its diverse landscapes, which include rolling plains, dense boreal forests, and numerous lakes and rivers.

The province is a major producer of grains and oilseeds, making agriculture a cornerstone of its economy. Saskatchewan is rich in minerals, particularly potash and uranium, and is a leader in energy production from oil, natural gas, and renewable methods. Its major cities, Regina, the capital, and Saskatoon, the largest city, are economic hubs of culture, education, and innovation.

The potash reserves in Saskatchewan are located within the Middle Devonian Prairie Evaporite Formation (a thick sequence of evaporite minerals such as halite and potash deposited in a restricted marine basin approximately 393 to 383 million years ago), in the Elk Point Basin, a region with a layered sedimentary history beginning from the Cambrian period (approximately 541 to 485 million years ago, characterized by a succession of carbonate, shale, and sandstone formations reflective of varied marine and coastal environments) (12).

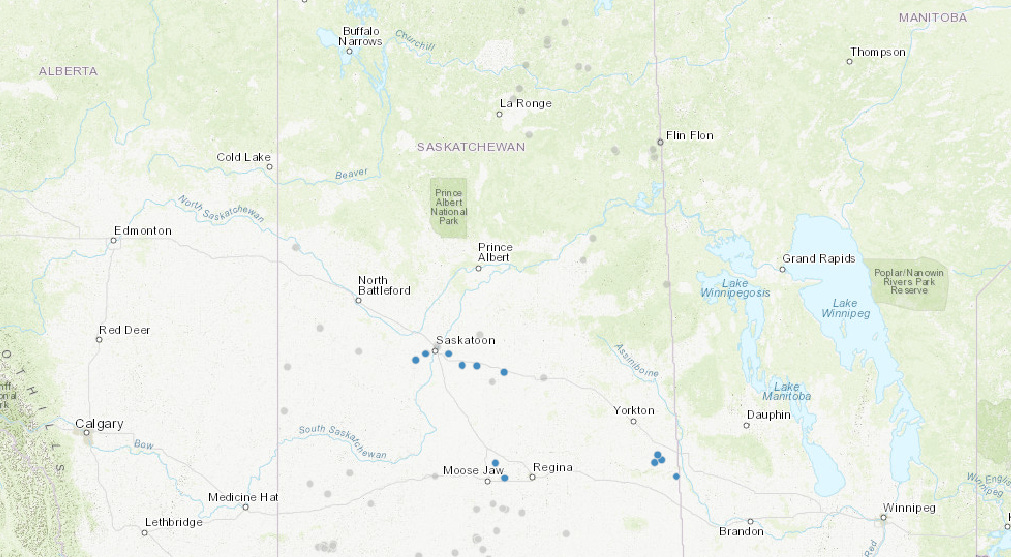

As of 2023, This region is home to ten active mines and several major development projects, collectively contributing to Canada’s position as the largest producer and exporter of potash globally, as shown in the map below. In 2022, these mines produced approximately 24.6 million tonnes of potassium chloride (KCl), reflecting a steady increase in production over previous years (14).

Following are the active potash mines in Saskatchewan.

Nutrien Ltd.

Allan Mine: Operating since the 1960s, this mine uses conventional underground mining techniques.

Cory Mine: Combines conventional underground mining with solution mining for deeper deposits.

Lanigan Mine: Relies exclusively on conventional underground mining methods.

Patience Lake Mine: Transitioned to solution mining after flooding halted underground operations in the late 1980s.

Rocanville Mine: Near the Manitoba border, Rocanville is one of Nutrien's largest and most productive operations, utilizing underground mining techniques.

Vanscoy Mine: Located southwest of Saskatoon, Vanscoy has been a cornerstone of Nutrien’s operations for decades, employing underground mining methods.

The Mosaic Company

Belle Plaine Mine: Among the largest solution mining facilities in the world, Belle Plaine is a flagship operation.

Colonsay Mine: Restarted in 2022 to meet rising global demand, this mine east of Saskatoon uses underground mining.

Esterhazy Mine: Mosaic’s largest operation, the Esterhazy complex includes K1, K2, and the advanced K3 shafts, all employing underground mining.

K+S Potash Canada

Bethune Mine: Opened in 2017 near Moose Jaw, Bethune is Canada’s first new greenfield potash mine in nearly 50 years. It employs solution mining and stands as a flagship project for K+S.

BHP

Jansen Mine: Set to become the eleventh potash mine in Saskatchewan, the Jansen project will utilize underground mining techniques.

Canada’s Potash Transportation System

Jointly owned by Nutrien Ltd. and The Mosaic Company, Canpotex represents the unified efforts of two of Saskatchewan’s largest potash producers for Canadian potash to reach over 40 countries, supporting global agriculture and food security.

The heart of Canpotex’s transportation system lies in its extensive fleet of over 8,000 custom-designed railcars. These cars, owned by Canpotex but operated on tracks provided by Canadian Pacific (CP) and Canadian National (CN), efficiently transport potash from Saskatchewan’s mines to major port terminals in Vancouver, British Columbia; Portland, Oregon; and Saint John, New Brunswick.

This integration of specialized railcars with Canada’s robust rail infrastructure allows Canpotex to load approximately 240 vessels annually, ensuring seamless delivery to international markets. Over the years, Canpotex has invested more than $1 billion USD to enhance its logistics network, including expanding its railcar fleet and upgrading terminal facilities (15).

Capex Requirement of Potash Megaprojects

Despite the apparent simplicity of the two main processing methodologies for potash—conventional underground mining and solution mining—these projects only economically viable through economies of scale.

Economies of scale are critical because potash prices, while occasionally experiencing spikes, tend to stabilize within predictable ranges, requiring high production volumes and cost leadership to offset initial expenditures.

Solution Mining Projects

Once mineral reserves are well established, building a solution mining operation involves a series of critical steps.

First is the development of the mine, which includes establishing the wellfield and creating caverns. A wellfield is a network of wells used to inject water into potash-rich deposits, dissolving the mineral to form underground caverns filled with brine, which is then extracted and processed to recover potash. Injection and production wells are drilled strategically to ensure efficient water and brine flow, enabling the dissolution and extraction of potash-rich brine.

Next is the construction of the processing plant, where the extracted brine is treated to separate and crystallize the potash. Alongside this, waste salt management systems are implemented to handle by-products responsibly, ensuring minimal environmental impact. These steps are supported by essential infrastructure, including pipelines, power systems, and transportation networks, which are critical for sustaining efficient operations and product delivery.

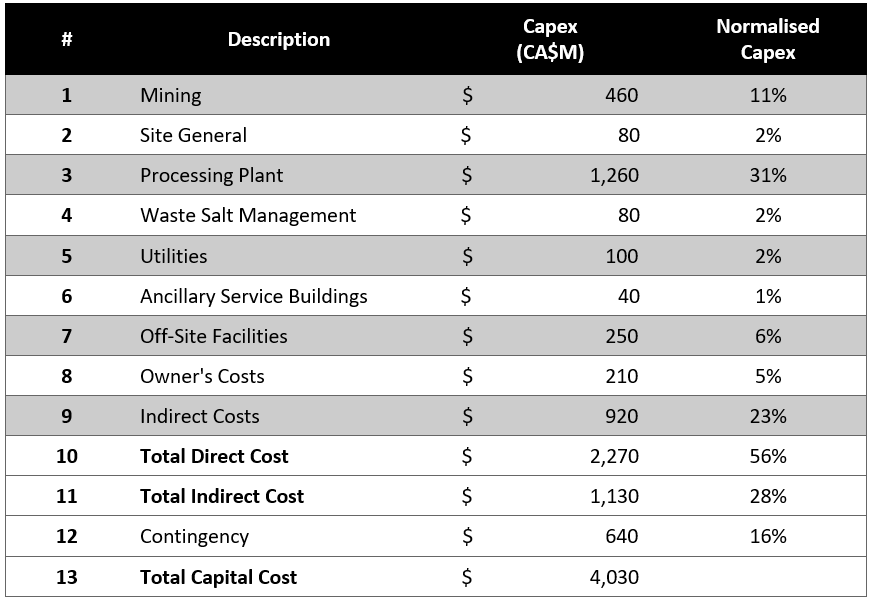

A Preliminary Economic Assessment for a 3.5 Mtpa (million tonnes per annum) solution mining project, published in 2017, estimated the total cost at CA$4.03 billion. The table below presents the rounded values and normalized percentages for the various components of the project. As anticipated, the normalized costs highlight the processing plant as the primary cost driver.

Conventional Underground Mining Projects

Developing a conventional underground potash mining project involves a series of carefully planned steps.

First is the development of the mine itself, which includes sinking shafts to access the potash deposit. These shafts serve as critical access points for workers, equipment, and material transportation, and are supported by ventilation systems to ensure a safe working environment. Mining is conducted using the room-and-pillar method, where large underground rooms are excavated, leaving pillars of potash to support the overlying strata. This method ensures stability while allowing efficient extraction of the resource.

The other major part is the construction of the processing plant, where the mined potash ore undergoes a series of critical steps to transform it into marketable products. This includes raw ore handling, storage, and crushing to prepare the material for processing. The process mill building is divided into wet and dry areas. The wet area comprises attrition scrubbing, desliming, flotation, and debrining, which are essential for separating the potash from impurities. The dry area involves drying, screening, compaction, and glazing to refine the product further. These operations are complemented by waste management systems, such as tailings storage, and infrastructure for transport, power, and water supply, ensuring efficient and sustainable production.

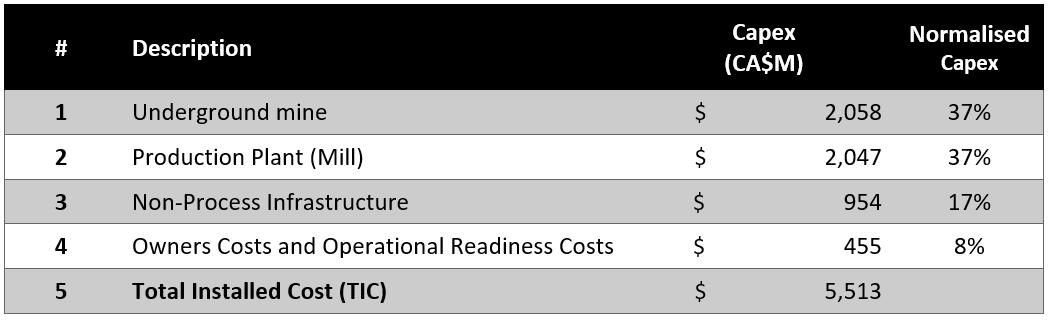

The most recent underground potash mine in Canada with a reported capital estimate is Jansen Stage 1. The conventional underground project, designed for 4.35 Mtpa production, was estimated to cost CA$5.513 billion in 2022. The table below presents the values reported by BHP along with normalized percentages.

Notably, the underground mine features one service shaft and one production shaft, both fully lined to ensure stability and operational efficiency. The processing plant includes facilities for processing and milling, encompassing both wet and dry operations as described earlier, along with tailings processing systems. Non-process infrastructure comprises essential components such as a tailings management area, administration buildings, warehousing, workshops, utilities, and rail connections. The normalized cost distribution highlights mining and processing as two equally significant components in the economics of underground potash project.

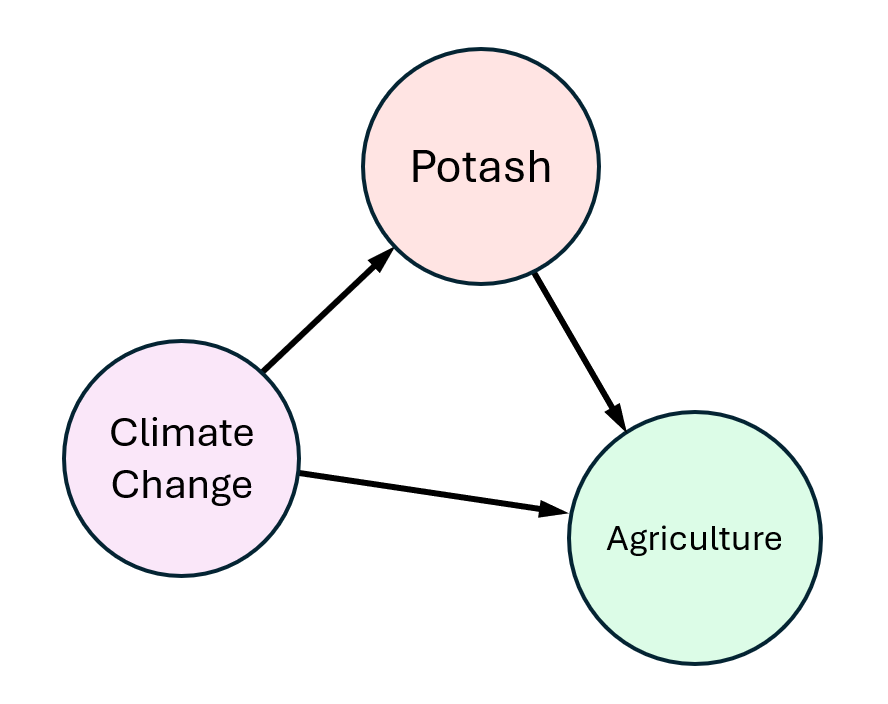

Potash and Climate Change Adaptation: A Curious Relationship

Potash serves as a major pathway for climate adaptation in the agriculture industry, particularly in enhancing drought resistance in crops (17, 18).

At the same time, Saskatchewan experiences some of the widest swings in both the temperature and precipitation in Canada (19), posing dire risks to Canadian potash industry.

This causal dependence should highlight the importance of climate change adaptation of the potash industry for its principle stakeholders, way above its resource wealth.

As a key source of potassium, potash plays a critical role in regulating water uptake and retention in plants, enabling them to maintain hydration even under arid conditions. These benefits make potash indispensable for farming in regions prone to erratic rainfall patterns, where the impacts of climate change are intensifying.

Furthermore, potassium aids in detoxifying reactive oxygen species generated under water stress, safeguarding photosynthesis and ensuring continued crop productivity. This dual role of conserving water and sustaining metabolic functions underscores potassium's pivotal role in developing climate-resilient agriculture systems, making potash an indispensable resource for global food security in a warming world.

The potash mining industry in Saskatchewan faces significant risks from climate change that directly challenge its operations and sustainability.

One of the most pressing issues is the increasing frequency of excessive moisture events and flooding. Such occurrences result in higher volumes of brine for disposal, escalating operational costs and creating logistical challenges for storage and treatment. This amplifies the necessity for robust infrastructure investments, including enhanced flood bypass systems and deep-injection wells, to mitigate operational disruptions and environmental risks.

Water scarcity and prolonged droughts is another major climate risk. Water is integral to potash extraction and processing, with both conventional and solution mining methods relying heavily on its availability. Climate-induced reductions in water quantity and quality could compromise operations and strain existing water supply systems. Mining companies have begun implementing water reuse and recycling initiatives, optimizing their consumption patterns, and exploring innovative sourcing options such as utilizing treated wastewater (20).

Bracing against long-term climate projections possibilities require a need for integrated adaptation strategies, regulatory support, industry collaboration, and scientific innovation to sustain the sector amid changing climatic conditions.

This underscores the broader challenge of aligning an old yet fast growing industry.

Question then Becomes

Our road trip through Canada’s potash heartland was a rewarding journey, offering firsthand insight into an industry that sustains global agriculture.

We saw first hand, the mines, the infrastructure networks, and landscapes that together deepened our appreciation for Canada’s vital role in feeding the world. It also gave us interesting questions to think about.

Canada’s potash industry, despite its economic importance, often lingers in the shadow of resource giants like oil and energy. This relative obscurity diminishes its potential significance as a major driver of development, both directly within Canada and indirectly across the world, as well as its role in a climate change adaptation pathway for the agriculture industry.

How can the Potash industry better present its role in global food security and secure its rightful place alongside Canada’s other flagship resource sectors? What steps, from strategic marketing to stronger policy support, could elevate its visibility and impact?

Potash offers an important opportunity for the mining industry to reshape its reputation by highlighting its contributions to alleviating hunger and promoting sustainable agriculture. How can the Canadian mining industry better embrace this narrative?

Notes

Refer to this article as below:

Zangeneh, P., Hassanpour R., F. (2025), “Canada’s Potash Legacy: A Road Trip Through 40% of the World’s Food Fertilizer Production,” EPM Research Letters.

Join the EPM Network to access insights, influence our research, and connect with a community shaping the industry's future.

Please support us by sharing this article with your friends and colleagues.

References

Al Rawashdeh, R. World peak potash: An analytical study. Resource. Policy 69, 101834 (2020).

Al Rawashdeh, R. & Maxwell, P. Analysing the world potash industry. Resource. Policy 41, 143–151 (2014).

Word Bank Group. https://datacatalog.worldbank.org/.

Broughton, P. L. Economic geology of southern Saskatchewan potash mines. Ore Geol. Rev. 113, 103117 (2019).

Fertilizer Canada - Growing Stronger. Fertilizer Canada, https://fertilizercanada.ca/.

Potash. https://www.thecanadianencyclopedia.ca/en/article/potash.

CMM. A Great Future in Potash. Canadian Mining Magazine https://canadianminingmagazine.com/a-great-future-in-potash/ (2024).

Saskatchewan Potash History – by John Burton (The Encyclopedia of Saskatchewan). Republic of Mining https://republicofmining.com/2014/03/18/saskatchewan-potash-history-by-john-burton-the-encyclopedia-of Saskatchewan-unknown-date/ (2014).

Saskatchewan Research Council. https://www.src.sk.ca/blog/helping-industry-produce-premium-potash-support-global-agricultural-community.

Saskatchewan potash nourishing the earth. http://saskmining.ca/ckfinder/userfiles/files/SMA-Potash-Infographic-2022-Stats-WEB.pdf

Saskatchewan potash vital for world food, https://www.resourceworks.com/saskatchewan-potash-vital.

Scientific Investigations Report. https://portergeo.com.au/database/mineinfo.asp?mineid=mn1801 (2023).

Government of Saskatchewan, https://geohub.saskatchewan.ca/datasets/saskatchewan::mine-locations/

Canada, N. R. Potash facts. https://natural-resources.canada.ca/minerals-mining/mining-data-statistics-and-analysis/minerals-metals-facts/potash-facts/20521 (2018).

Canpotex. https://www.canpotex.com/news/canpotex-invests-its-world-class-supply-chain-acquiring-1300-railcars-national-steel-car.

BHP, https://www.bhp.com/what-we-do/global-locations/canada/jansen

https://www.icl-group.com/blog/the-role-of-potash-in-sustainable-agriculture/

Sardans, J. and Peñuelas, J. (2015), Potassium stoichiometry and global change. Global Ecology and Biogeography, 24: 261-275. https://doi.org/10.1111/geb.12259

Haave, D. (2012). WUQWATR Climate Extremes Preparedness Workshop Final Report. Wascana Upper Qu’Appelle Watershed Association Taking Responsibility (WUQWATR)

Pittman, J., Ford, J. & Pearce, T., 2014. Adaptation to climate change and potash mining in Saskatchewan, Canadian Electronic Library. Ottawa, Ontario. Retrieved from https://coilink.org/20.500.12592/x10208 on 15 Jan 2025. COI: 20.500.12592/x10208.